Wood Stabilization in a Glass Vac Chamber 101

, by Mike Pabich, 5 min reading time

, by Mike Pabich, 5 min reading time

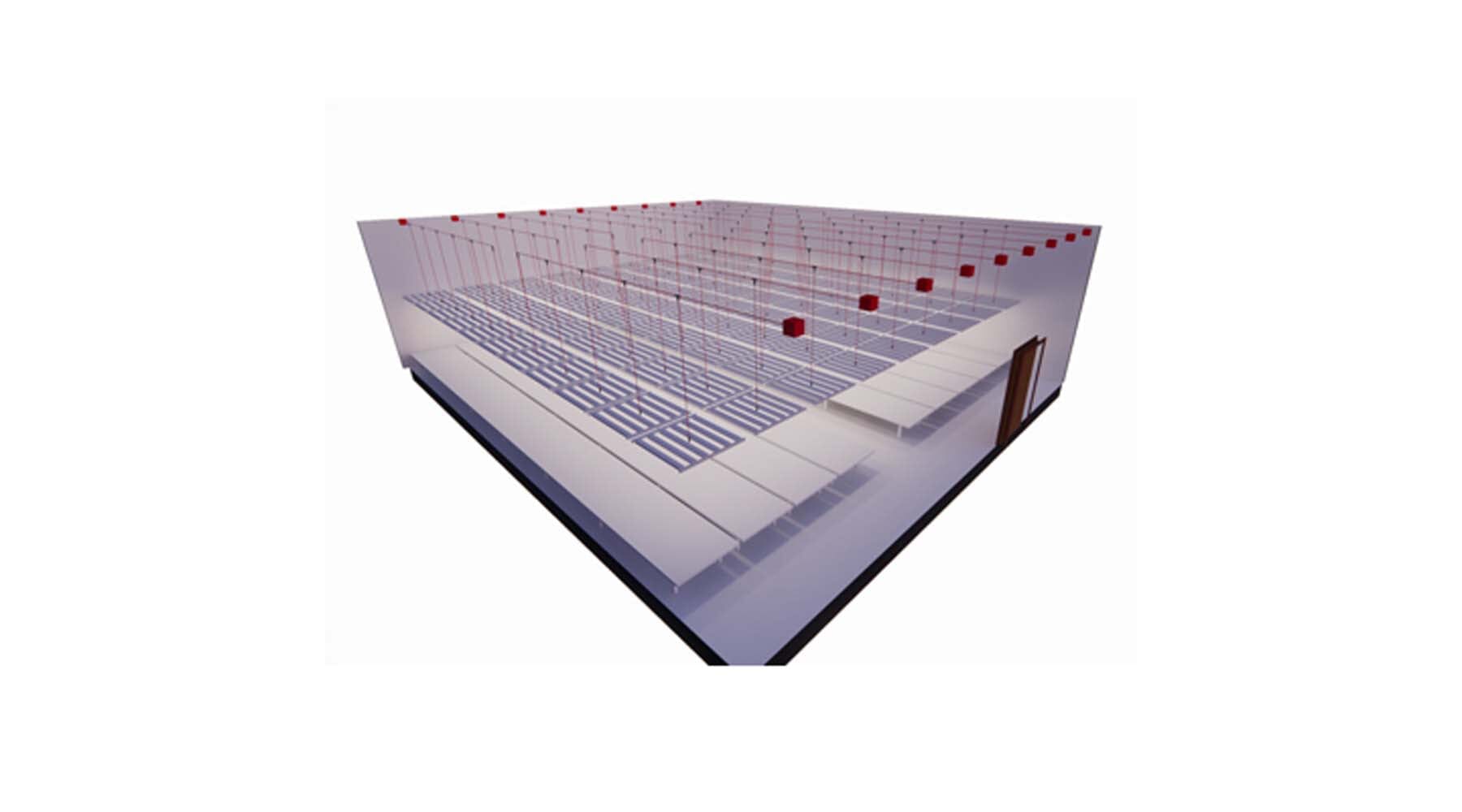

Woodturners unite: wood stabilization is made easy with Cactus Juice and our Glass Vac Chambers. No, we’re not talking about the popular cactus juice beverage from Mexico and South America (in case you were wondering). The professional grade, heat-cured resin called Cactus Juice will become your best friend if you frequently deal with absorptive woods. Cactus Juice that is injected into wood blanks combined with the power of a vacuum chamber will yield more stable, glossy, moisture-resistant wood that’s easier to turn.

Woodturners unite: wood stabilization is made easy with Cactus Juice and our Glass Vac Chambers. No, we’re not talking about the popular cactus juice beverage from Mexico and South America (in case you were wondering). The professional grade, heat-cured resin called Cactus Juice will become your best friend if you frequently deal with absorptive woods. Cactus Juice that is injected into wood blanks combined with the power of a vacuum chamber will yield more stable, glossy, moisture-resistant wood that’s easier to turn.

For those who’ve never cured blanks with a vacuum chamber before, here’s a beginner’s guide to show you just how easy stabilizing wood is with our Glass Vac Chambers.

There is often confusion between the differences of applying pressure versus vacuuming. With the right equipment, the amount of pressure one could use is infinite. Vacuuming, on the other hand, has a limit. A vacuum by definition is a space devoid of matter. This isn’t achievable even in near-perfect settings like laboratories or outer space. BUT, since those of us in industrial labs or outer space are few and far between, using the right vacuum pump can get us as close as humanly possible.

In layman’s terms, a vacuum will remove the atmospherically compressed air that is in the wood and make room for the Cactus Juice. The more air that evacuates the chamber, the more the Cactus Juice will disperse into the wood and create more stability.

First and foremost, you must make sure your blanks are dry before stabilizing. Your moisture meter should read that moisture is below 10%. If it’s not, simply warm them up in an oven at 220° F for at least 24 hours, making sure they’re not baking so much they crack. It’s crucial to let them cool in a Ziploc bag or airtight container immediately after removing them from the oven to prevent the hot wood from absorbing moisture from the air.

Before you put the blanks in the chamber, double-check to make sure the vacuum itself is stable and not in a place where it could easily fall, spill materials, or implode. Now, it’s time to add the Cactus Juice. Place the cooled blanks in the Glass Vac chamber and weigh them down so they stay submerged. Then, pour in enough Cactus Juice to cover the blanks completely by about 1-2 inches. Close the lid and apply pressure as needed to make sure the gasket is totally sealed.

When you start the vacuum, it will be pulling an incredible amount of air from the blanks and cause the juice to bubble up considerably. Keep the foaming under control by opening the valve completely before starting to pump and then gradually, slowly close it. Once all major foaming has subsided, go ahead and apply full vacuum.

It could take anywhere from 30 minutes to many hours to saturate the blanks. Keep the vacuum going for however long it takes for you to see VERY few bubbles coming from the wood, a signal of little moisture. When all air has discharged, release the vacuum and turn the pump off. The blanks need to soak for twice as long as they were in the vacuum. But, when in doubt, err on the side of caution and soak them longer; it will make a noticeable difference than under-soaking.

After the blanks have thoroughly soaked, put on durable gloves to remove them from the chamber and drain the excess Cactus Juice. Now begins the curing process, where heat will be reapplied to permanently seal the resin.

Preheat your oven to 190-200° F and double-check the temperature with a thermometer for optimal accuracy. Before entering the oven, wrap the blanks individually in aluminum foil so they don’t accumulate into one solid lump. The internal temperature of the blanks needs to reach 190-200° F for at least 10 minutes for the Cactus Juice to set.

Depending on the wood’s thickness, it usually takes 1-1.5 hours to cure. It certainly doesn’t hurt to let them cook longer, as long as you’re sure they’re ready when you take them out; if the blanks cool without fully curing, putting them back in the oven will not help. You can check if the blanks are done by taking them out, putting on good gloves, and peeling back a corner of the foil. Immediately put back in the oven for another hour or two if you see any liquid Cactus Juice.

When you’re sure the blanks have finished curing, you can remove the foil and let them cool to room temperature. And presto! You’ve cured and stabilized the wood! An added step would be scraping off loose resin that has come off the blanks. It’s not a requirement, but you might find it helpful because you’ll be able to see the blank better and be certain what to use it for.

Proper maintenance of a Best Value Glass Vac Chamber is equally important for long-term use. Even if you only used it five minutes, change the oil on your machine after each use and wash the chamber with dish soap and a rag before using it again. Leftover Cactus Juice can be saved for later in plastic containers; the juice will cure on its own if it’s stored in glass jars. For more maintenance and warranty information, check out our FAQ’s.